Ultrasonic Wall Thickness Gauges

Ultrasonic Wall Thickness Gauges (ultrasonic thickness gauges, ultrasonic thickness testers, ultrasonic thickness meters, UT gauges, etc.) measure the wall thickness of materials such as steel, plastic, and more using ultrasonic technology. Ultrasonic Thickness Gauges are ideal for measuring the effects of corrosion or erosion on tanks, pipes, or any structure where access is limited to one side. Multiple echo Thru-Paint models (UTG M) measure the metal thickness of a painted structure without having to remove the coating.

What is Ultrasonic Thickness Measurement?

Ultrasonic thickness measurement techniques are used to measure a wide range of substrates and applications for loss of material thickness due to corrosion or erosion. Ultrasonic Thickness Gauges are designed for measuring the thickness of metallic (cast iron, steel, and aluminum) and non-metallic (ceramics, plastics, and glass) substrates and any other ultrasonic wave-conductor provided it has relatively parallel top and bottom surfaces.

An ultrasonic thickness gauge facilitates rapid inspection of the thickness of large metallic structures at small measurement intervals, providing a high-detail thickness map of a scanned surface. When access is only available from one side of the substrate, ultrasonic wall thickness measurement is the most efficient way to monitor the effects of erosion or corrosion and is instrumental to both quality assurance and quality control.

PosiTector UTG C Series

Corrosion probes measure the wall thickness of materials such as steel, plastic, and more. Ultrasonic Thickness Gauges are ideal for measuring the effects of corrosion or erosion on tanks, pipes, or any structure where access is limited to one side.

- 5 MHz dual element transducer

- Our most ultrasonic thickness popular probes for measuring the effects of corrosion on steel substrates

- Select from cabled, integral, and Xtreme probes

Options include:

PosiTector UTG C Corrosion with Cabled Probe

PosiTector UTG CA Corrosion with Integral Probe

PosiTector UTG CX Corrosion with Xtreme Probe (Pictured)

PosiTector UTG M

Thru-Paint capability to quickly and accurately measure the metal thickness of a painted structure without having to remove the coating. Also ideal for measuring blasted materials and other applications requiring a more durable wear face.

- 5 MHz contact probe with wear resistant alumina probe tip and cabled probe

- Multiple-Echo technique averages 3 or more echoes for accurate and reliable readings

- Toggle between Single and Multiple-Echo modes

- Multiple Echo mode eliminates coating thickness

- Single Echo mode detects pits/flaws and increases measurement range

PosiTector UTG M

Low frequency ultrasonic thickness probes measures the wall thickness of attenuative materials such as cast/ductile iron, cast aluminum, and cast zinc.

- Low frequency 2.25 MHz dual element transducer with cabled probe

- Proprietary algorithm distinguishes back wall reflections from grain noise (reflections) found in cast materials

- Ideal for measuring attenuative materials such as cast iron

PosiTector UTG P

Precision Ultrasonic Thickness Meters are designed for high resolution measurements and thin materials including metals and plastics. Automatic Multi-Echo mode ensures the best accuracy on thin metals.

- 15 MHz Single element delay line with cabled probe

- Automatic single-echo or multiple-echo mode depending on material thickness

- Automatic probe tip temperature compensation

- Ideal for thru-paint applications to quickly and accurately measure the metal thickness of a painted structure without having to remove the coating

- Precision probe ideal for thin materials

- Minimum steel measuring range: 0.008" (0.2 mm)

- Minimum plastic measuring range: 0.005" (0.125 mm)

Principles of Operation of Ultrasonic Wall Thickness Gauges

Why Measure Wall Thickness with Ultrasonic Thickness Gauges?

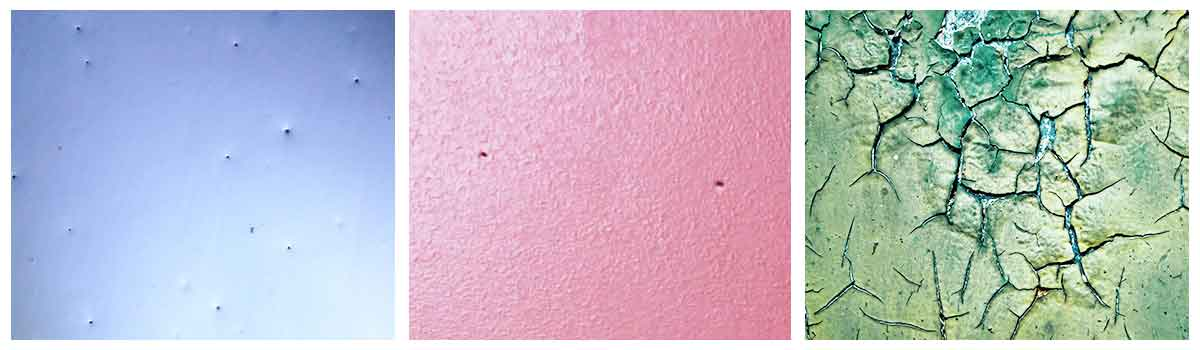

Erosion

Erosion is the process by which a protective coating or substrate is worn away by friction resulting from repetitive mechanical interaction. Typical causes of erosion include cavitation, impingement by liquid or solid particles, and relative motion against contacting solid surfaces or fluids.

Corrosion

Corrosion is the process by which a substrate and its properties are damaged or worn away by a chemical action or change. In metals, deterioration attributed to corrosion is most often caused by an oxidation process.

Erosion and Corrosion Testing

Using non-destructive inspection methods minimize safety concerns, ensure code compliance, and reduce the frequency of major repairs (and subsequently costs). As an example, marine applications have a significant risk of catastrophic substrate failure due to undetected substrate corrosion or erosion. However, costs associated with corrosion or erosion damage can be more subtle. Consider the case of a propeller blade that has experienced wear or damage. A likely impact is a decrease in the efficiency of the propeller, translating directly to a decrease in horsepower and an increase in turbulence (vibration). This results in a decrease in maximum speed and an increase in fuel consumption. Furthermore, cavitation caused by the damaged propeller creates a surrounding environment that is even more damaging to the propeller itself.

What are some UT Measurement Applications?

With ultrasonic thickness gauges, an accurate measurement of the remaining wall thickness of a substrate can be taken on pipes, pressure vessels, storage tanks, boilers, or other equipment prone to erosion or corrosion.

Though many industries are affected by erosion and corrosion, the marine atmosphere is one of the most aggressive corrosion environments. Corrosion rates are affected by several elements including sea water, humidity, wind, temperature, airborne contaminants, and biological organisms. Erosion is also common in marine applications due to abrasion from the impact of water and contaminate particles, impingement due to turbulence in high speed liquids, and cavitation due to pressure waves produced by air bubbles. Erosion not only affects the substrate itself but may also damage protective coatings, increasing the likelihood of substrate corrosion. Ships, marinas, pipelines, offshore structures, and desalination plants are all systems that are subject to varying levels of marine erosion and corrosion.

What is the difference between the PosiTector UTG C, PosiTector UTG M, and PosiTector UTG P probes?

The PosiTector UTG C Ultrasonic Thickness Gauge (Corrosion) single echo probe uses a dual-element transducer, a focused “V-path”, and V-path compensation to accurately measure the thickness of metals with heavy corrosion or pitting. The UTG C single echo probe will not ignore the thickness of the exterior coating: for best measurement accuracy, it may be necessary to remove any coating present at the point of measurement.

The PosiTector UTG M Ultrasonic Thickness Gauge (Multi-echo) probe uses a single element transducer to accurately measure the metal thickness of a new or lightly corroded structure while ignoring the thickness of protective coatings. The ultrasonic beam travels in a straight path to the material’s back wall at 90° relative to the surface. When three consecutive back wall echoes are detected, the probe makes a time-based calculation to eliminate the coating thickness from the gauge reading.

The PosiTector UTG P Ultrasonic Thickness Gauge (Precision) probe uses a single element delay line transducer to accurately measure the thickness of thin materials including plastics and metals. It automatically switches between single-echo or multiple-echo modes depending on material and thickness.

Theory of Operation of Ultrasonic Wall Thickness Gauges

Single Echo

Single-echo PosiTector UTG C probes feature a dual element transducer with automatic V-Path compensation. Thickness is determined by measuring t1 (uncoated) or t2 (coated), dividing it by two and then multiplying by the velocity of sound for that material (steel). See Figure 1.

Figure 1

For uncoated materials, t1 related directly to material thickness. When a material is coated, the propagation time is increased and is shown above as t2.

Coatings such as paint have a slower velocity of sound than that of metal. Thus the single echo technique will produce a thickness result greater than the actual combined coating and metal thickness. The result will include a significantly higher, unknown value of paint thickness. Therefore, it is not a simple matter of measuring the thickness of the paint and subtracting it from the single echo measurement result.

Multiple Echo

The PosiTector UTG M and UTG P ultrasonic thickness probes in multiple-echo mode determine thickness by measuring the time between at least three consecutive back wall echoes.