PosiTector DPM (Dew Point Meter) Probes

Digital Dew Point Meters

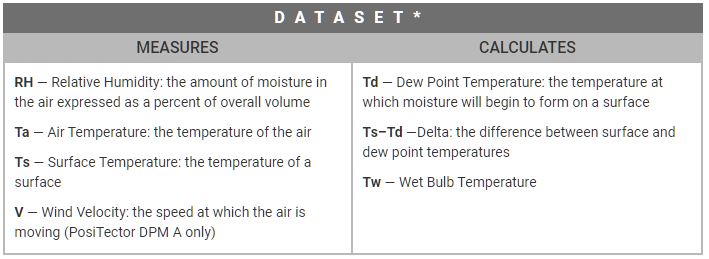

Depending on the model selected, PosiTector DPM Dew Point Meters measure and record climatic conditions including: relative humidity (%RH), air temperature, surface temperature, dew point temperature, the difference between surface and dew point temperatures (Delta), wind speed, and wet bulb temperature.

PosiTector DPM L (Dew Point Meter Standalone Logger)

Autonomous Dew Point Meter Loggers

The PosiTector DPM L Dew Point Meter Logger attaches to steel structures to measure and record environmental parameters independently for up to 200 days. Stored readings can be downloaded using a PosiTector Advanced gage body or Apple/Android smart device.

PosiTector IRT (Infrared Thermometer probe)

Non-contact Infrared Surface Temperature Thermometer

The PosiTector IRT non-contact Infrared Thermometer measures surface temperatures in areas where conventional sensors will not work including hard to reach areas, moving parts, freshly sprayed powder coating, and objects whose temperatures are above the range of direct contact sensors.

Principles of Operation

What is a Dew Point Meter?

A Dew Point Meter measures and records climatic conditions including: relative humidity (%RH), air temperature, surface temperature, dew point temperature, the difference between surface and dew point temperatures (Delta), and wet bulb temperatures.

Why are Dew Point Meters used to measure environmental conditions?

Environmental conditions are monitored and recorded using handheld, portable Dew Point Meters during surface preparation, application, and cure of paints and coatings. Doing so allows paint and coatings applicators to determine when optimal environmental conditions are met—greatly reducing the likelihood of costly reworks and premature failure of the coating or paint systems.

How is relative humidity (%RH) measured?

Relative Humidity is the amount of moisture in the air expressed as a percent of overall volume. High relative humidity can retard the rate of solvent evaporation.

Traditionally, relative humidity (RH) was calculated using the wet and dry bulb temperature measurements taken from a sling psychrometer (whirling hygrometer). Sling psychrometers consist of two thermometers called dry bulb and wet bulb with the latter being covered in a wet sock (wick) saturated with water. Sling psychrometers are whirled rapidly for 90 seconds causing the liquid water to evaporate and for the wet bulb to read lower than the dry bulb. After the appropriate amount of time, both bulbs are measured and the results are converted to humidity measurements using psychometric tables, graphs, or slide rules. From there, the results were compared to those obtained from a surface temperature thermometer.

Convenient, modern electronic dew point meters have simplified humidity and temperature measurements negating the need for complex lookup tables or slide rule calculators. Multifunctional dew point meters have the ability to take immediate and continuous readings of all relevant environmental parameters that are less subject to operator interpretation and measurement errors, as well as calculation and rounding errors associated with the use of lookup tables.

The multipurpose PosiTector DPM Dew Point Meter is ideal for continuous measurement of air temperature, surface temperature, and percent relative humidity.

How is dew point measured?

Dew point (dewpoint) is the temperature at which moisture will begin to form on a surface. Dew point is a function of air temperature and relative humidity and is described as the temperature to which a volume of air must be cooled in order to reach saturation.

Undiscovered condensation on freshly blasted steel may result in flash rusting and premature coating failure if a thin, invisible film of moisture is trapped between the coating and the substrate. To ensure optimal performance of the coating system, ISO 8502-4 and SSPC guidelines recommend that the surface temperature must be a minimum of 5°F or 3°C above the dew point during the 3 critical phases of painting—surface preparation, coating application, and the cure cycle.

Traditionally, dew point was calculated using a sling psychrometer and complex look-up tables or psychometric slide-rule calculators. Sling psychrometers are limited since they are subject to interpolation errors, cannot be used for continuous monitoring, and do not offer memory storage.

Chilled mirror hygrometers measure dew point using a chilled mirror, light beam, and light detector. As the air is cooled, dew would form on the mirror, blocking the light, and indicating that the air has reached the dew point. While this technique worked well in a laboratory environment, it was less effective for the steel structure painting industry due to their bulk, fragility, and cost.

Modern dew point meters such as the PosiTector DPM can immediately calculate dew point by measuring surface temperature and relative humidity using precision temperature and humidity sensors. Some meters calculate dew point only, but the more practical instruments include a surface temperature probe. Surface temperature probes (sensors) allow the users to calculate and display the important delta value—the difference between the surface and dew point temperatures.

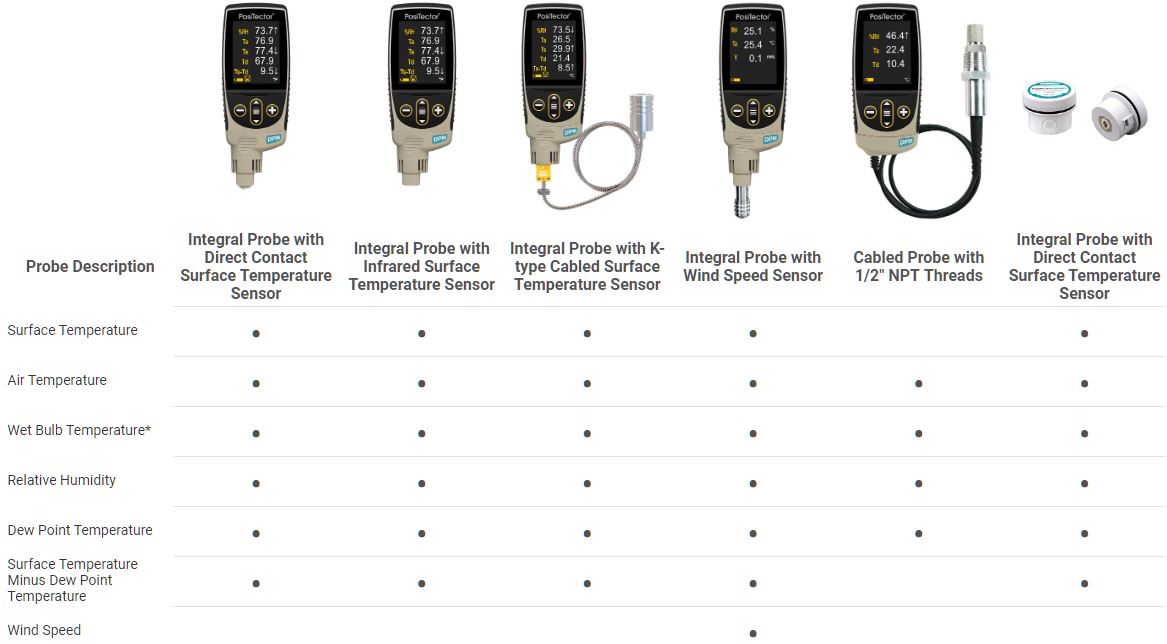

What are the available dew point meter models?

Which Dew Point Meter is right for my application?

There are four key decisions when selecting a dew point meter:

First, it is important to identify the environmental parameters that need to be monitored. Generally, the surface, air, and wet bulb temperatures; relative humidity; and dew point temperature can be measured or calculated. Some dew point meters, such as the PosiTector DPM will be able to calculate Delta as well. Measuring surface temperature is critically important since it is the substrate temperature that determines whether or not moisture will form on the surface. Surface and Ambient temperatures can vary dramatically due to factors such as direct sun, shade, and even the shape and mass of the structure.

Second, if there is a surface or part that needs to be monitored, consider how easy it will be able to access that surface. Will it be too hot for conventional surface temperature sensors? Out of reach? Dew point meters equipped with an infrared surface temperature sensor, such as the PosiTector DPM IR can accomplish this measurement while still measuring and calculating other parameters.

Third, do the environmental conditions need to be monitored over a period of time or would instantaneous measurements suffice? All PosiTector DPM models measure instantly and also feature Auto Log mode for continuous measurement. Advanced models feature an enhanced Auto Log mode that turns the instrument off between readings for up to 8 months of battery life. The PosiTector DPM L is designed specifically for autonomous monitoring, and features up to 200 days of battery life in a small enclosure.

Finally, are there memory and/or reporting requirements? All PosiTector DPM Standard models can store up to 2,500 datasets. All PosiTector DPM Advanced models can store up to 250,000 datasets or 1,000 batches. The PosiTector DPM L Dew Point Meter Logger can store up to 10,000 datasets (60,000 readings). Software solutions are available for viewing, analyzing, and reporting data.

What environmental parameters are measured with dew point meters?

Depending on which PosiTector DPM model is selected, a dataset can consist of five or more of the environmental parameters below.

Standard models feature storage of 2,500 datasets.

Advanced models can store up to 250,000 datasets.

The PosiTector DPM L can store up to 10,000 datasets.

When is it safe to paint?

The difference between the surface temperature and the dew point temperature is the most critical, determining factor for the long-term performance of coatings and linings on steel structures.

Documents such as ASTM D3276 and the international standard ISO 8502-4 state that the surface temperature must be a minimum of 5°F (3°C) above the dew-point temperature during the critical 3 phases of coating: preparation, application and cure. This minimum separation also helps allow for surface temperature reduction as solvents evaporate or when cold coating materials are applied.

If the dew point temperature is below this minimum separation, or even if they are close, the risk on moisture forming on the steel surface may be unacceptably high and may lead to coating failure.

Why is it important to measure dew point in compressed air?

When air is compressed, the gasses (oxygen, nitrogen, etc.) become more dense. As a result, the liquid water vapor within that air can easily reach saturation, especially in warmer environments such as factories.

Some industries monitor compressed air systems for moisture and dewpoint temperatures since moisture can have a negative effect on the adhesion, color, and gloss of spray-applied coatings using compressed air. Wet compressed air can cause damage to components allowing rust and corrosion to build up. Most problems can be avoided by simply monitoring dew point temperatures in compressed air systems.