Surface Profile Measurement Gauges

Why is Surface Profile Measurement Important?

Steel is often abrasive-blast cleaned or otherwise roughened prior to painting. The peak-to-valley height of the resultant "surface profile" is a critical and determining factor in the performance of applied paint and other protective coatings. A surface profile height that is too low may reduce coating bond strength (adhesion). Too high and the peaks may receive insufficient coverage leading to premature rusting, and often require additional paint (and labor costs to apply it) to cover the anchor profile.

Emerging research over the past 15 years has shown surface profile height is not the only important parameter. Peak density (also known as peak count), the number of peaks in the surface profile per unit area, has been shown to be a strong determinant of coating adhesion and resistance to corrosion. In fact, studies have found that peak density may be a better predictor of coating performance than peak-to-valley height.

Surface profile height can also be relevant for other industries, as a way to quantify the profile height of non-skid surfaces, and to evaluate the Concrete Surface Profile (CSP) prior to applying coatings on concrete.

See below for more information about surface profile measurement and gauge solutions.

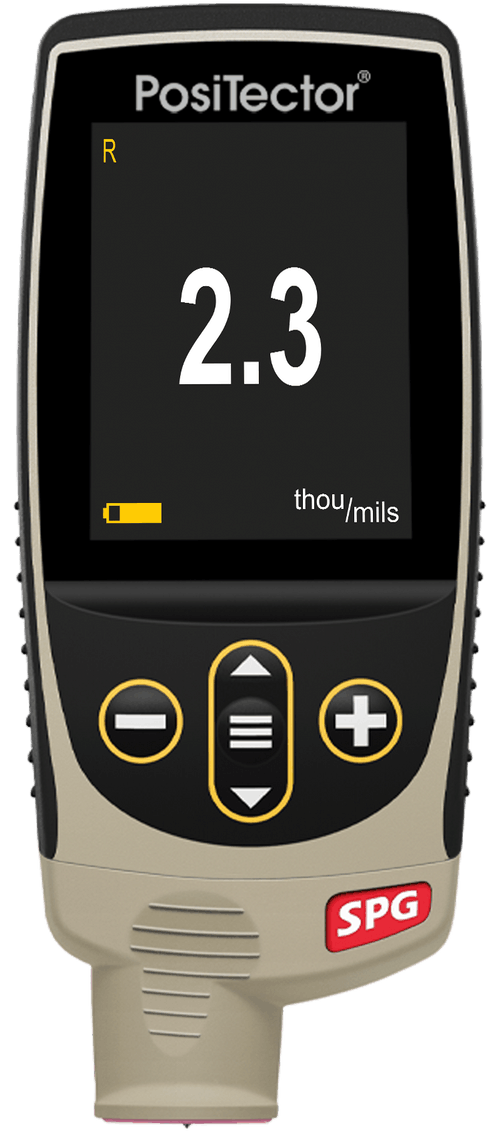

PosiTector SPG Surface Profile Gage

Surface Profile Gages use a digital depth micrometer fitted with a fine pointed probe to measure and record peak-to-valley surface profile heights in preparation for the application of coatings.

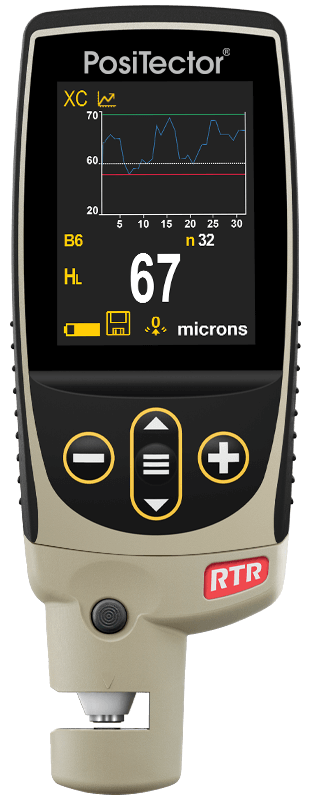

PosiTector RTR H Replica Tape Reader

Digital spring micrometers measure and record surface profile parameters using Testex Press-O-Film™ replica tape—producing a more accurate peak-to-valley surface profile height measurement for blasted steel and textured coatings.

PosiTector RTR 3D Replica Tape Reader

Digital replica tape imagers measure and record 14 common 2D/3D surface profile parameters using Testex Press-O-Film™ replica tape. Download high resolution .SDF files for further analysis (Advanced models only).

Conforms to ASTM D7378.

How is Surface Profile Measured?

Achieving optimal surface profile is a critical part of surface preparation* before the application of paint, coatings, liners, and cementitious overlays. By using standardized test methods and instrumentation, identifying optimal surface profile is possible—reducing the chance of coating adhesion failure, preventing corrosion, creating ideal paint finishes, and installing resilient cementitious overlays. Measuring anchor profile is essential for QA/QC and to achieve the high-performing and resilient coatings systems that clients expect.

*See also: Soluble Salt Testing and Environmental Monitoring

There are a variety of methods available to determine surface profile and concrete surface profile (CSP) peak-to-valley height, each with differing levels of accuracy and efficiency. Depending on whether a blasted steel surface or a concrete surface is being measured, different tools and instruments can be used.

The most common methods of determining surface profile on blasted steel surfaces include depth micrometers, replica tape readers, replica tape imagers, and drag stylus roughness gages.

Depth Micrometers for Blasted Steel

Depth micrometers fitted with a flat base and fine pointed probe such as the PosiTector SPG, are a low per-test-cost method that use a spring-loaded tip which drops into the valleys of a blasted steel surface to measure peak-to-valley height. With a greater range than replica tape and most stylus roughness instruments, they are a quick and reliable way of determining surface profile.

To take a measurement with a PosiTector SPG Surface Profile Gage (digital depth micrometer):

1

Ensure the surface is free of all dust and other contaminants.

2

Place the probe foot level on the surface to be measured.

3

The depth micrometer will display the profile height on-screen.

DeFelsko manufactures different models suited for a variety of applications—view the PosiTector SPG ordering guide for more information.

Testex Press-O-Film Replica Tape Readers for Blasted Steel

Replica tape readers such as the PosiTector RTR H or PosiTector RTR 3D use Testex Press-O-Film™ replica tape to determine the anchor pattern of the blasted steel substrate. It is simple, relatively inexpensive, and is particularly useful on curved surfaces.

To take a measurement with a PosiTector RTR Replica Tape Reader (digital spring micrometer):

1

Prepare: Clean the surface with a putty to remove dust and other contaminants.

2

Burnish: Place the replica tape (Testex Tape) on the substrate and burnish; the compressible foam within the tape forms a reverse replica of the surface.

3

Measure: Insert the replica tape between the PosiTector RTR's measurement anvils and take a reading.

How to Select the Right Surface Profile Instrument for the Field

Read, "Replica Tape - A Source of New Surface Profile Information" for more information.

Stylus Roughness Testers for Blasted Steel

Drag stylus roughness instruments operate by dragging a stylus at a constant speed across the blasted steel surface being measured. The instrument records the up and down distances the stylus travels as it traverses across the surface and averages the vertical distance between the highest peak and lowest valley (Ra).

Some stylus roughness testers may leave scratches on the surface being measured, potentially contributing to future defects that could cause premature rusting and coatings failures. Additionally, the precise stylus assembly tends to be somewhat fragile, so field use may not be ideal. Lastly, stylus roughness tester’s probe tips can be prone to degradation and reading accuracy may suffer.

Read “Surface Profile - A Comparison of Measurement Methods” to learn more about these three methods and how they compare.

Other Methods to Measure Surface Profile on Blasted Steel

Optical Methods/Laser Profilometers—Used in laboratory settings, these devices generally rely on wavelengths of light to measure the anchor profile of a surface. Laser Profilometers are very accurate but due to their form factor and expense, are prohibitive for in-field use.

See the PosiTector RTR 3D optical replica tape reader as a potential alternative.

Comparative Methods—Comparative methods are usually in the form of a small square or disc and blasted to a particular profile with designated abrasive types. Surface comparators offer the user a subjective test to quickly assess a substrate’s anchor profile. Beware when using older comparators as they may have acquired surface wear and may not accurately represent the profile they once had.

Measuring Concrete Surface Profile

The most common methods of determining concrete surface profile (CSP) include depth micrometers, replica putty, and visual comparators.

Depth Micrometers for Concrete Surface Profile

Depth micrometers such as the PosiTector SPG TS, are a no per-test-cost method that use a spring loaded tip (60°—conically shaped) which drops into the valleys of a concrete surface profile to measure peak-to-valley height.

While less expensive methods are available, depth micrometers offer a means to quantitatively record readings in a statistically meaningful way.

Replica Putty

Replica putty is a means of creating a permanent replica of a CSP, similar in concept to replica tape. A 2-part compound is combined then pressed into the surface of a concrete slab. It is then removed and allowed to cure. Using a comparative reference, a subjective profile is assumed.

Comparative Methods

Using molded-rubber "chips"; subjective, comparative assessments may indicate a general profile of a concrete surface. Comparative methods are efficient in that they offer a quick check, but do not provide a quantitative means to measure and record the profile of a concrete surface.

Measuring Profile of Textured Coatings

The profile of textured coatings is often challenging to measure with most depth micrometers, stylus roughness instruments, and replica tape readers due to their greater peak-to-valley heights.

Depth Micrometers for Textured Surface Profile

Depth micrometers with an extended range of 0–60 mils (0–1,500 μm) such as the PosiTector SPG CS are an ideal choice for measuring textured coatings.