Impermax H Flex Aluminium

DESCRIPTION

Impermax Polyurea H Flex Alum is a 2-component polyurea resin, which cures very fast into an elastic membrane with crack-bridging capacity. This product can only be applied by 2-component spraying equipment. Impermax Polyurea H Flex Alum can be combined with different geotextiles to obtain on-site applied, seamless liners (Rayston Spray liners). It can be also pigmented with aluminium particles pigments to obtaing sun-reflective properties.

APPLICATION

Waterproofing of concrete structures and bridge decks. Impermax Polyurea H Flex not need an additional UV-resistant coating. Roof waterproofing. Waterproofing of water tanks, channels…containing neutral water (not potable). Geomembrane lining for retention basins and secondary containment structures, ponds, landfills, tunnels, canals, dam reparations, etc. Waterproofing of foundations, especially those designed as barriers to Radon gas.

COLOUR

Aluminium

CERTIFICATIONS

- Fire test B2 (DIN 4102-1:1998): Ignitability when subjected to direct

- impingement of flame. Class B2

- Reaction to external fire as per EN 13501-5:2007+A1:2010: Broof(t2)

- ETA: European Technical Assessment document Nº 16/149

- (ETAG033) – CE marking

- Hail resistance according to EN 13583:2012

- Radon diffusion coefficient according to ISO 11665-13

Impermax H Flex

DESCRIPTION

Impermax Polyurea H Flex is a 2-component polyurea resin, which cures very fast into an elastic membrane with crack-bridging capacity. This product can only be applied by 2-component spraying equipment. Impermax Polyurea H Flex can be combined with different geotextiles to obtain on-site applied, seamless liners (Rayston Spray liners). It can be also pigmented with aluminium particles pigments to obtain sun-reflective properties. Highly resistant to meteorological phenomena, especially hail. Radón gas barrier which is naturally generated in the earth's crust.

APPLICATION

Waterproofing of concrete structures and bridge decks. Impermax Polyurea H Flex can be completed with an additional UV-resistant coating. Roof waterproofing. Waterproofing of water tanks, channels…containing neutral water (not potable). Geomembrane lining for retention basins and secondary containment structures, ponds, landfills, tunnels, canals, dam reparations, etc. Waterproofing of foundations, especially those designed as barriers to Radon gas.

COLOUR

Spray pigment is supplied for Blue 5015, Grey RAL 7011, Tile, Beige RAL 1001. Other colours to pastes under request.

CERTIFICATIONS

- Fire test B2 (DIN 4102-1:1998): Ignitability when subjected to direct

- impingement of flame. Class B2

- Reaction to external fire as per EN 13501-5:2007+A1:2010: Broof(t2)

- ETA: European Technical Assessment document Nº 16/149

- (ETAG033) – CE marking

- Hail resistance according to EN 13583:2012

- Radon diffusion coefficient according to ISO 11665-13

Impermax H

DESCRIPTION

Impermax Polyurea H is a polyurea resin, applied with a hot spray machine, totally free of solvents and mineral fillers. Once cured, it forms a totally continuous waterproofing membrane

(without joints or overlaps), of high mechanical and external resistance, thermoset and elastomeric (with the ability to bridge the possible fissures of the support). The membrane heals in a few seconds and its commissioning is in a few hours.

APPLICATION

• Waterproofing of roofs, terraces and balconies on different types of supports (concrete, metal, old asphalt fabrics, prefabricated membranes ...), always using a suitable primer.

• Waterproofing and protection of concrete structures, especially those exposed to the outside.

• Protective finish of polyurethane insulating foam.

• Waterproofing of foundations and buried structures.

COLOUR

Spray pigment is supplied for Blue 5015, Grey RAL 7011, Tile, Beige RAL 1001. Other colours to pastes under request.

PROPERTIES

• Fully continuous, thermoset, flexible and elastic membrane, with an excellent ability to bridge possible fissures of the support.

• Extremely fast curing and commissioning.

• Possibility of high solar reflectance finishes type "cool roof" with the Colodur Pigmented in white.

• It can be exposed to the outside or covered by tiles, concrete or other material. Being a membrane of aromatic nature, if it is exposed to sunlight it is recommended to protect it with an aliphatic protective finish (Colodur Pigmented or Impertrans Eco) to maintain its aesthetic appearance over time.

• Resists continuous contact with stagnant (neutral) water on decks.

CERTIFICATIONS

• ETA: European Technical Assessment nº 11/062 (W2 10 years), certificate of resistance to root penetration is included, based on EN-13948.

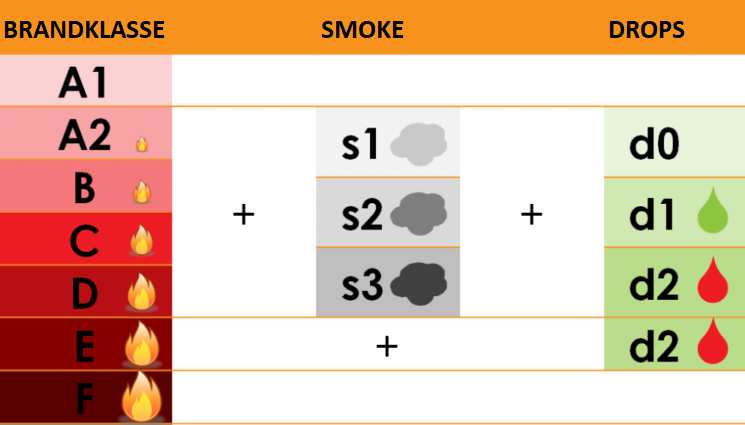

• Reaction to fire class: Cfl-s1, based on EN-13501-1.

Impermax 2K

.jpg)

DESCRIPTION

Impermax 2K is a 2-component polyurethane resin with Root penetration resistance (EN 13948), which cures very fast into an elastic membrane with crack-bridging capability. This product can only be applied by 2- component spraying equipment.

APPLICATION

- Waterproofing of concrete structures, roof, terraces, etc.

- Waterproofing of water tanks.

- Component of parking deck systems for light traffic applications (see Impermax Park system).

See Manual of Waterproofing Systems of Krypton Chemical for further details.

CERTIFICATIONS

- ETA: European Technical Agreement Document Nº 10/0296 –

- 25 year CE marking.

- Root penetration resistance (EN 13948)

- Applus certification laboratory:

- Drinking water contact. Migration test. No 928/09/470d7395

- (2010). External fire behaviour: Document No. 10/101587/1223

- (2010)

- Istituto Giordano (Italy)

- Asbestos fibre encapsulation (UNI 10686:1998), report 325389 (2015)

- AITEX. Mechanical properties EN ISO 527-1/3, Static Indentation / CBR as per

- UNE-EN ISO 12236:2007, Tear Strength UNE-EN ISO 34-1:2011.

- DOP: 15 - 590

Impermax H Supreme

DESCRIPTION

Extremely high elongation membrane for the most demanding applications onto substrates exposed to very high / low temperatures or with expansion / contraction movements. It has more than 600% elongation and recovers completely after exposure to tensile forces, behaving like a pure elastomer. Low and even viscosity for A and B components makes it very easy to apply this material with 1:1 spray equipment. It is recommended to use only flexible and elastomeric top coats to protect this product from UV, like our Impertrans resin.

APPLICATION

Flexible seamless polyurea-based flooring. Waterproofing of concrete structures. Impermax Polyurea H Supreme can be completed with an additional UV resistant coating. Roof waterproofing. On-site applied, totally seamless linings for secondary containment, ponds, landfills, tunnels, canals, dam reparations.

PROPERTIES

- Crack bridging ability.

- Highly elastic membrane.

- Fast curing.

- Pigmentable with Pigment Spray

CERTIFICATION

CE marking EN 1504-2: 0370-CPR-2247, .

Rayston X5 (foam+polyurea)

DESCRIPTION

Polyurea Rayston X5 is a polyurea system that increases its volume 3 to 5 times and helps to fill all voids and height differences in substrates of different nature.

The product has good mechanical properties and in some decks not exposed to traffic may be used as a waterproofing membrane and using the right top coat (Impertrans / Colodur / Impertop Fast 2K, Impermax A). The product may also be used as a primer onto substrates like bitumen felt, etc before application of 2 - 3mm polyurea for 25 year guarantee under ETAG 005.

APPLICATION

- Primer onto different height / uneven ROOFING substrates (bitumen, metal, fibrecement).

- Waterproofing membrane for roofs and decks not exposed to traffic (metal, fibrecement, etc).

- Comfort layer in flooring areas needing a cushioning / shock absorption capacity

- Product has a limited puncture resistance compared to pure or hybrid polyurea membranes. Use in decks and roofs not exposed to traffic.

COLOUR

Spray pigment is supplied for Blue 5015, Grey RAL 7011, Tile, Beige RAL 1001. Other colours to pastes under request.

CERTIFICATIONS

Fire test B2 (DIN 4102-1:1998): Ignitability when subjected to direct impingement of flame. Class B2

Reaction to external fire as per EN 13501-5:2007+A1:2010: Broof(t2)

ETA: European Technical Assessment document Nº 16/149 (ETAG033) – CE marking

Hail resistance according to EN 13583:2012

Radon diffusion coefficient according to ISO 11665-13

Polyurea Rayston

DESCRIPTION

Polyurea Rayston fast is a 2- component pure polyurea system for elastic membrane application with crack-bridging capability. It is an extra fast-curing system that can only be applied by hot mechanical spraying equipment. Polyurea Rayston can be combined with different geotextiles to obtain on site applied, seamless liners.

PROPERTIES

· Crack-bridging capability. Highly elastic membrane.

· Very fast curing, using two component spraying equipment.

· It can be pigmented.

APPLICATION

Waterproofing of concrete structures. Roof waterproofing. Sewage and wastewater treatment structures. Onsite applied liners, totally seamless, for secondary containment applications, ponds, landfills, tunnels, canals, dam repairing.

Polyurea Rayston can be completed with an aliphatic polyurethane topcoat to ensure UV protection.

COLOUR

Spray pigment is supplied for Blue 5015, Grey RAL 7011, Tile, Beige RAL 1001. Other colours to pastes under request.

CERTIFICATIONS

- CE marking EN 1504-2: 0370-CPR-2247, • ETA (ETAG005): European Technical Assessment document Nº 16/0148 Applus (Independent laboratory)

- Drinking water certification (Migration test). 928/09/8505

- Contact with alcoholic beverages. Simulation C as per regulation EU

- 10/2011 (EN 1186): pass. Certificate 928/11/4106 M1

- Low-temperature foldability: 11/2855-1313

- Mechanical properties: 11/2855-1314

- Dynamic and Static indentation test according to EOTA. 11/2855-

- 1315

- Contact with fuel products (UNE 48307:2011) Exp 13/6620-457

- External fire resistance EN 13501-5:2005+A1 :2010

- Water Regulations Advisory Scheme LTD. (WRAS) Material Approval (United Kingdom , contact with water intended for human consumption). Approval number 1709541 AITEX (Independent laboratory):

- Mechanical properties EN ISO 527-1/3.

- Static indentation/CBR UNE-EN-ISO 12236:2007.

- Tear, according to UNE-EN ISO 34-1:2011

Polyurea Rayston P

copy.png)

DESCRIPTION

Polyurea Rayston P is a system based on pure polyurea with balanced viscosity of ISO and POLY for easier set up of the pressure of proportioner machine! Two components with viscosity (25°C) A= 420mPa.s B=425mPa.s

Extra fast curing for the application of elastic membranes, with crack bridging. Only applied by hot mechanical projection.

The product can be combined with different geotextiles to obtain "liners" without application joints in continuous.

APPLICATION

• Waterproofing of concrete structures.

• Roof waterproofing.

• Liners of on-site application, totally continuous, for secondary containment, rafts,

landfills, tunnels,

• canals, repair of dams, reservoirs, etc.

• Wastewater facilities.

• Polyurea Rayston P can be coated with aliphatic polyurethane to provide UV protection to color change.

Waterproofing of all type of hydraulic infrastructures also wastewater installations (high resistance to H2S)

Waterproofing of foundations, especially those designed as barriers to Radon gas.

COLOUR

Spray pigment is supplied for Blue 5015, Grey RAL 7011, Tile, Beige RAL 1001. Other colours to pastes under request.

PROPERTIES

• Crack bridging capability.

• Membrane of high elasticity, totally continuous.

• Very fast curing with application by hot projection equipment for two components.

• Pigmentable

Rayston Fire E

DESCRIPTION

Rayston Fire E is a pure polyurea resin with Reaction to fire classification according to EN-13501-1: B-s2-d0, totally free of solvents. Spray applied with a proportioning machine (ratio 1:1 in volume). Once cured, it forms a continuous and seamless high performant membrane, chemical, fire and outdoors resistant, that has got a thermosetting and elastomeric behaviour (hard and elastic at the same time). The membrane cures in a few seconds and returned to service in a matter of hours.

APPLICATIONS

Coating, protection and waterproofing of concrete structures (indoors and outdoors, tunnels for example). Protection of metallic supports.

PROPERTIES

• Fully continuous membrane, hard, elastic and flexible. High puncture and compression resistant, able to bridge over cracks in the support.

• Very fast curing, using two-component spraying equipment.

• Outstanding fire resistance. Does not spread fire.

COLOUR

Spray pigment is supplied for Blue 5015, Grey RAL 7011, Tile, Beige RAL 1001. Other colours to pastes under request.

CERTIFICATIONS

Reaction to fire classification according to EN-13501-1: B-s2-d0.

Rayston Spray AC P350

DESCRIPTION

Rayston Spray AC P350 is a two-component pure polyurea resin ideal for anticorrosive application on metal surfaces with System C5H certified, according ISO 12944-6:2018, which cures very fast into a hard and elastic membrane. This product can only be applied by 2-component spraying equipment.

APPLICATION

• Industrial machinery and vehicle protection.

• Marine applications.

• Linning of tanks containing chemicals, pipe coating.

• Excellent protective anticorrosion protection (barrier protection) with high durability.

COLOUR

Spray pigment is supplied for Blue 5015, Grey RAL 7011, Tile, Beige RAL 1001. Other colours to pastes under request.

PROPERTIES

• Flexible, hard membrane.

• Fast curing.

• Pigmentable.

• Very good chemical resistance.

• Very good abrasion resistance.

• Very low permeability to Radon gas, methane gas and carbon dioxide gas.

• For steel structures in high, very high and extreme atmospheric corrosivity categories (C3, C4, C5-ISO12944-2/2018).

CERTIFICATES

System C5H certified, according ISO 12944-6:2018

Rayston Spray D50

DESCRIPTION

DESCRIPTION

Rayston Spray D50 is a 2-component pure polyurea resin, which cures very fast into a hard and elastic membrane. This product can only be applied by 2-component spraying equipment.

APPLICATION

Water tanks containing aggressive chemicals

Industrial machinery and vehicle protection

COLOUR

Spray pigment is supplied for Blue 5015, Grey RAL 7011, Tile, Beige RAL 1001. Other colours to pastes under request.

PROPERTIES

- Flexible, tough, hard membrane

- Very good chemical resistance

Mechanical properties

Hardness Shore: 50D / 96A

Elongation at break: 270% Tensile strength: 17.2 MPa (UNE EN ISO 527-1/3)

Tear strength: 100 N/mm

Rayston Spray P5060

DESCRIPTION

Rayston Spray P5060 is a hard protective coating specially formulated for expanded polystyrene (EPS) foam.

This product can only be applied by 2-component spraying equipment.

APPLICATION

• Covering EPS foam and phenolic foam, as an ict protection

• Industrial machinery and vehicle protection

COLOUR

Spray pigment is supplied for Blue 5015, Grey RAL 7011, Tile, Beige RAL 1001. Other colours to pastes under request.

PROPERTIES

• Hard-flexible membrane

• Fast curing

• Pigmentable

Polyurea H SLS

DESCRIPTION

New slow-reacting hybrid polyurea developed for manual application & Hot spray with static mixer, with a working time of approximately 20 minutes, this time period allows you to sprinkle colorful arids, flakes… to obtain a more resistant or decorative finish depending on project requirements the curing time of 3-4 hours, no smell at all !!!!!

Application with hot spray machine & static mixer.

A1- Time to work

Working time: 18 minutes

Tack free: 1 hour

Works on the flooring 3 hours (without sand & 2,5 kg/m2)

A2- Topcoat layer

Anti-slip topcoat

Polyurea H SL is a 2-component polyurea resin, which cures into a hard membrane for flooring applications, and allows sand broadcasting ont the fresh product.

Self levelling polyurea ideal for flooring application with Gel time mixture A+B at 25-30 min !!

APPLICATION

General fast-applied flooring systems. Decorative and industrial floors, where fast application is needed.

COLOUR

Spray pigment is supplied for Blue 5015, Grey RAL 7011, Tile, Beige RAL 1001. Other colours to pastes under request.

consult.

Chemical resistance

Surface contact 24 h, room temperature

Product Results

Water - 5

Isopropyl alcohol - 3

Xylene - 0

Sodium hydroxide 20% - 5

Sodium hydroxide 33% - 5

Sodium hydroxide 50% - 5

Glycerine ( 50% in water) - 5

Sulphuric acid 10% - 5

Ammonia 3% - 4

(5=Best, 0=Worst)