Leading the way with spray gun Innovation

DeVilbiss invented the world’s fi rst “stand alone” HVLP and COMPLIANT technology spray guns back in the 1980’s. This resulted in a revolution in the way our spray guns atomise paints and set the bench mark in paint transfer efficiency, saving paint for the end users and dramatically reducing the emission levels of harmful VOC’s into the atmosphere. These and other patented ground breaking product developments have placed Binks and DeVilbiss at the summit of spray equipment manufacture for many years.

DEVILBISS® Manufactures low pressure manual and automatic spray guns and related spraying accessories; including air fi lter reducing valves and regulators, operator breathing systems, spray gun cups, hoses and other equipment for Finishing Markets. DeVilbiss is widely recognised for the development and introduction of the first “Compliant” spray guns, which greatly reduce overspray and VOC emission into the environment. The company’s expertise in ergonomics and innovative spray gun design is widely acclaimed.

This atomisation type was introduced by DeVilbiss in the mid 1990’s and is a ground breaking combination of Conventional and HVLP atomisation methods. Trans-Tech utilities more compressed air energy for the atomisation process producing much higher Transfer Efficiency of coating material than the Conventional method. This ‘complies’ with Global legislation by being able to transfer at least 65% of the sprayed material to the component. Air Cap Pressure is typically 1.3 to 3 BAR (20 to 45 psi). HVLP has mostly been replaced by DeVilbiss Trans-Tech Atomisation in most applications due to its superior finish qualities.

The most established method of air atomising used on “conventional” spray guns, uses relatively high velocity compressed air to provide good atomisation of the sprayed material. However this process results in low paint transfer e¤ ciencies due to the ‘bounce-back’ and ‘overspray’ generated. Compressed air operating pressures used in this process are typically 2 to 4 BAR (30 to 60 psi).

This “compliant” atomisation method fi rst became important in the 1980’s when environmental legislation was fi rst introduced. It uses larger compressed air volumes at lower pressures to atomise the coating. It has a much higher transfer e¤ ciency than Conventional Air Spray. However, the droplet size produced tends to be slightly larger, sometimes resulting in a lower quality fi nish. HVLP operates at 0.7 BAR (10 psi) at the air cap in compliance with global environmental legislation to provide greater than 65% transfer e¤ ciencies.

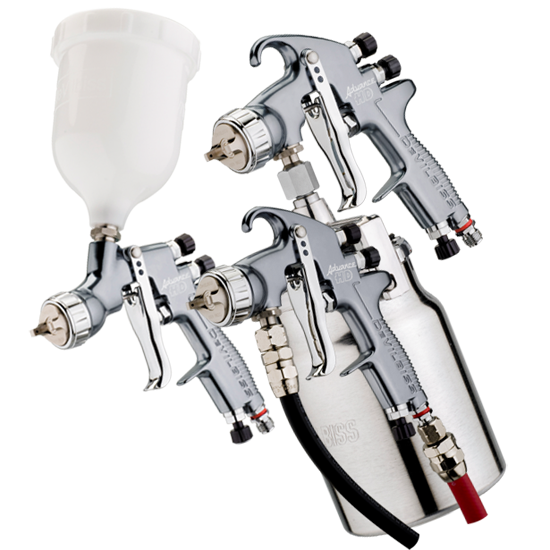

The all purpose mid-sized Compliant Spray Gun Range

The DeVilbiss Advance HD spray gun range ensures there’s a DeVilbiss spray gun to suit all types of industrial spray finishing applications.Pressure, Suction and Gravity feed, the DeVilbiss Advance HD family utilise a comprehensive, wide range of Compliant Air Caps to provide outstanding coatings’ atomisation for handling all types of solvent, waterborne, high solids and 2K materials.

- Robust, Lightweight and work friendly design for High Demand outputs

- Balanced air valve design for lighter trigger pull and improved air flow

- Trans-Tech Compliant and HVLP air caps provide superior finish with the best possible paint savings and transfer efficiency

- Contoured handle design – Greatly reduces RSi and operator fatigue

- Stainless Steel tips, needles and fluid passageways as standard

- CE marked and fully ATEX approved.

MATERIALS : Metal, Wood, Plastic, Ceramic, Other Substrates

APPLICATIONS : Aircraft & aerospace, Agricultural & construction, machinery, Ceramic, Defense & military, Domestic appliances & electronics, Drums & containers, General industry, Glass, Leather goods & shoe makers, Leisure, caravans & rv’s, Marine, shipping & boating, Rail, truck & bus, Trade coaters, stove enamelers, Wood

ADVANCE HD HVLP AND TRANS-TECH

ADVANCE HD CONVENTIONAL

| Air Supply Connection | Universal 1/4" (fits ¼” BSP and 1/4" NPS male) |

| Maximum Static Air Inlet Pressure | P1 = 12 bar (175 psi) |

| Maximum Static Fluid Inlet Pressure | P2 = 14 bar (203 psi) |

| Fluid Supply Connection | Universal 3/8" (fits 3/8” BSP and 3/8” NPS male) |

| Service Temperature | 0 to 40°C (32 to 104°F) |

| Gun Weight (gun only) / (cup only) | 495g / 420g |

Devilbiss spray technology has Advanced again...

The comprehensive Advance HD (High Demand) spray gun range ensures there’s a DeVilbiss spray gun to suit all types of industrial spray finishing applications. Pressure, Suction and Gravity feed, the DeVilbiss Advance HD family utilise a comprehensive, wide range of Compliant Air Caps to provide outstanding coatings’ atomisation for handling all types of solvent, waterborne, high solids and 2K materials.

DeVilbiss expertise and performance unequalled at work...

Advance HD unrivalled high performance is achieved with new design technology utilising high capacity air passages with a separate “balanced” air valve to provide an unrestricted flow of compressed air through the gun body. This “free breathing” air movement enables the precision-engineered air caps and fluid tips to produce superior atomisation with consistent even distribution throughout the spray

pattern. DeVilbiss Advance HD is precision built using the best materials and component parts for a guaranteed, reliable, long and durable working life in all industrial markets.

DeVilbiss Advance HD – Naturally comfortable...

Light weight with a lighter trigger action and increased finger room. DeVilbiss Advance HD is perfectly balanced and naturally comfortable thanks to the fit and feel of the contoured handle design. It greatly reduces operator fatigue and significantly lessens the chances of RSI or finger problems. Comfort that pays off by increasing productivity wherever DeVilbiss Advance spray guns are used, whether it’s a small finishing operation or a high volume production line.

Models | Air consumption | Air in pressure | Fluid flow | Fan pattern size |

| 430 | 339 lt/min | 3.5 bar | 200-280ml | 200mm |

| 443 | 345 lt/min | 3 bar | 200-300ml | 300mm |

| 462 | 380 lt/min | 3 bar | 500-1800ml | 450mm+ |

| 470 | 465 lt/min | 3 bar | 500-1800ml+ | 420mm+ |

| 477 | 480 lt/min | 3 bar | 200-800ml | 430mm |

| 497 | 510 lt/min | 3.5 bar | 200-600ml | 380mm |

*All illustrated flow rates and fan sizes may vary according to paint/material viscosity and pressure used.

MATERIALS : Metal, Wood, Plastic, Ceramic, Other Substrates

APPLICATIONS : Aircraft & aerospace, Agricultural & construction, machinery, Ceramic, Defense & military, Domestic appliances & electronics, Drums & containers, General industry, Glass, Leather goods & shoe makers, Leisure, caravans & rv’s

Marine, shipping & boating, Rail, truck & bus, Trade coaters, stove enamelers, Wood

- Wide range of conventional atomisation air caps provide a superior sprayed finish

- Robust, Lightweight and work friendly design for High Demand outputs

- Stainless Steel tips, needles and fluid passageways as standard

- Contoured handle design – Greatly reduces

- CE marked and fully ATEX approved

- The DeVilbiss Advance HD (High Demand) spray guns are available in Pressure, Suction and Gravity feed formats and a wide range of conventional technology Air Caps provide exceptional atomisation for coating wood, metal, plastic, ceramic and composite substrates with most types of solvent, waterborne, high solids and 2K materials. Advance HD’s unique high capacity airflow and outstanding atomisation characteristics are combined with a separate “balanced” air valve to provide an unrestricted flow of compressed air through the gun body, this coupled with light, feel right comfort is an unbeatable combination. DeVilbiss Advance HD spray guns are ideal for small operations or high volume spraying, with the added bonus of instantly improved finishing productivity. Advance HD is precision built by DeVilbiss using the best materials and component parts for a guaranteed, reliable, long and durable working life in all industrial markets.

Advance HD – Naturally comfortable...

Light weight with a lighter trigger action and increased finger room. Advance HD is perfectly balanced and naturally comfortable thanks to the fit and feel of the contoured handle design. It greatly reduces operator fatigue and significantly lessens the chances of RSi or finger problems.

Comfort that pays off by increasing productivity wherever DeVilbiss Advance spray guns are used, whether it’s a small finishing operation or a high volume production line.

DeVilbiss outperforms the rest.

Advance HD’s unique high capacity airflow and outstanding atomisation characteristics are combined with a separate “balanced” air valve to provide an unrestricted fl ow of compressed air through the gun body, this coupled with light, feel right comfort is an unbeatable combination.

Gti PRO LITE

| PRO Lite Weight: | Suction (gun only) 500g Gravity (gun only) 446g |

| Max Air Inlet Pressure | (P1): 12 bar (P2): 15 bar |

| Air Consumption | TE10: 275 l/min TE20: 350 l/min HV30: 465 l/min |

| Max Operating Ambient Temperature | 40°C Nominal |

| Gun Body Material | Anodized Aluminium |

| Fluid Passageway Material | Aluminium |

| Air Cap Material | Nickel plated Brass |

| Fluid Nozzle & Needle Materials | Stainless Steel |

| Seals & O rings | HDPE, FEPM |

| Trigger | Chrome plated Steel |

APPLICATIONS

Woodworking, Metal fabrication, Adhesives, Aerospace, Yacht & Marine, Railway & Rolling stock, Truck & Vehicle, Manufacture

Comprehensive range of Conventional, HVLP and Trans Tech (High Efficiency) Air Caps for choice of Transfer Efficiency,

Atomisation power and Application requirements.

Extensive range of stainless steel, hardened and tungsten carbide fl uid tips and needles for all types of industrial applications.

Coaxial trigger air valve design for lighter trigger pull and improved air flow.

Drop forged aluminium gun body and removable air ba² e for a longer working life.

Fully Environmental Legislation Compliant with high transfer efficiency resulting in signify cant paint savings.

Air adjuster valve provides instant “on gun” pressure adjustment for the sprayer.

Fully ATEX certified

Professional spray equipment for Fine Finishing. DeVilbiss expertise and performance unequaled at work...

The GTi PRO Lite spray gun family ensures there’s a DeVilbiss spray gun to suit all types of spray finishing applications. Pressure, Suction and Gravity feed, the range utilities a comprehensive range of new development Air Caps and fluid nozzles to provide outstanding atomisation for handling all types of Industrial solvent based and water based coatings.

The PRO Lite is precision built using the highest quality materials and component parts for a guaranteed, reliable, long and durable working life in all markets. A drop forged aluminium body with tough anodized external finish, high grade stainless steel fluid tips and needles and nickel plated hard brass air caps all contribute to a gun that can last in the extreme environment of the spray shop.

When routine maintenance is needed then the simple design and easy to maintain format ensures minimum down time and interrupted production. Enhanced ergonomics combined with DeVilbiss’ legendary fi t and feel ensure incredible performance, handling and balance.

JGA AND GFG PRO

Air Cup C1:

Recommended Inlet Pressure: 2.5 – 3 Bar (36-44 psi)

Air Flow @ 3 Bar/ 44 psi: 250 – 300 l/min (9 – 11 scfm)

Air Cup C2 :

Recommended Inlet Pressure: 2.5 – 4 Bar (36 – 58 psi)

Air Flow @ 3 Bar/ 44 psi: 255 – 400 l/min (9 – 14 scfm)

Air Cup C3:

Recommended Inlet Pressure: 2.5 – 4 Bar (36 – 58 psi)

Air Flow @ 3 Bar/ 44 psi: 260 – 410 l/min (9 – 15 scfm)

Air Connection: 1/4″ Universal

Fluid Connection: 3/8″ Universal

Gun weight (without cup): 650g

The ‘full size’ Conventional spray gun range

Renowned DeVilbiss Atomisation Quality

Genuine fast application rates

Forged aluminium gun body for long life service

Light smooth trigger action to reduce operator fatigue

Balanced air valve design to improve air fl ow characteristics.

MATERIALS

Industrial solvents, Water based, paints, Coatings, Lubricants, Dyes, Stains, Varnishes,

Lacquers, Adhesives

APPLICATIONS

Aircraft & aerospace, Agricultural & construction machinery, Defense & military

Domestic appliances & electronics, Drums & containers, General industry

Glass, Leather goods & shoe makers, Leisure, caravans & rv’s, Marine, shipping & boating, Rail, truck & bus, Trade coaters, stove enamels, Wood

The World’s favorite spray guns just go better

with the introduction of the new JGA / GFG PRO range. The DeVilbiss JGA & GFG PRO are high performance conventional air atomising guns suitable for most spray finishing applications and are made of the best available materials to withstand the highest demands in the modern spray shop, to provide a guaranteed, long and durable working life. The guns can be used with virtually all solvent and water based paints, coatings, lubricants, dyes, stains, varnishes, lacquers and adhesives.

PRO LITE E

Max Air Inlet Pressure (P1): 12 bar

Max Fluid Inlet pressure (P2): 15 bar

Max Operating Ambient Temperature: 40°C Nominal

Gun Body Material: QuickClean™ Coated, Drop Forged Aluminium

Fluid Passageway: Material Stainless Steel

Air Cap Material: Nickel plated Brass

Weight: 525 gr

Size (W x H x D): 170 x 175 x 18 (43mm dia head)

Fluid Nozzle & Needle Materials: Stainless Steel, Nitride coated Stainless, Steel, Tungsten Carbide

Seals & O rings: HDPE, FEPM

Air Inlet connection: 1/4” Universal

Fluid Inlet connection 3/8”: Universal

The perfect gun for enamel, ceramic and glaze applications with drop forged aluminium body, QuickcleanTM black gun body coating and specialized needle packing for a longer working life.

Extensive range of stainless steel, hardened and tungsten carbide fluid tips and needles for all types of ceramic applications.

Increased diameter Stainless Steel large bore Fluid Passageways for fluid flows up to 3.5 L/min with heavy weight ceramic glaze.

Exclusively designed for heavy duty spray finishing and surface coating

CERAMIC & ENAMEL INDUSTRY

The DeVilbiss PRO Lite E is an enhanced version of the PRO lite exclusively designed for heavy duty spray finishing and surface coating applications in the ceramic and vitreous enamel market.

The combination of highly abrasive coatings plus high fluid flow rates present particularly difficult conditions for application equipment, and the DeVilbiss

PRO Lite E has been designed for continuous and reliable

performance in this environment. The standard gun body forging is first coated with our specially developed QuickcleanTM coating to reduce cleaning time and improve durability even more. Then the coated gun body is machined and fitted with a fluid passageway liner so that the fluid only ever touches stainless steel taking away.

Finally the gun is fitted with a special abrasion resistant needle packing to withstand the aggressive action of ceramic coating on the sliding needle shaft.

CSPRAY Yacht spray

CDT Pressure Air Cap

| Air Consumption | 540 i/min |

| Air Inlet Pressure | 3.5 bar |

| Typical Fluid Flow | 200-500 cc/min |

| Typical Fan Width | 430 mm |

CDTG Pressure Air Cap

| Air Consumption | 345 lt/min |

| Air Inlet Pressure | 3 bar |

| Typical Fluid Flow | 200-300 cc/min |

| Typical Fan Width | 300 mm |

PLUS: The CDT and CDTG air caps, which are unique to the Cspray gun range are manufactured and certified by DeVilbiss to guarantee ultimate and superior performance. This means that every CDT air cap is spray tested with paint, in 12 different air cap angle positions, each position is then compared against master Engineering spray pattern’s for all of these key parameters:-

- Fan Size / Fan Shape / Droplet Distribution / Concentricity of spray fan with fluid needle.

- Cspray handles these paints: Single and 2 pack Water or Solvent based paints, High, Medium and Low Solids, Solid Colour Top coat and Clear coat

- Metallic and Pearlescent Top coat, Undercoat and Primers, Anti-Foul paints

The DeVilbiss spray gun range especially for the Yacht and Light Marine market

- Designed in partnership with the Market Leading Paint Manufacturers. NEW Critical Droplet atomisation Technology (CDT) air caps provide enhanced performance and best finish right across the range of Marine paints. Cspray has Stainless Steel tips, needles and *fluid passageways as standard. Curved gun handle – Enhances gun handling and greatly reduces operator fatigue. Lightweight gun design with lighter trigger pull and improved air flow.

The moment you pick up and handle the Cspray gun with the unique blue finish you will realize this gun is special.

DeVilbiss has worked with the leading marine paint companies to evolve the Cspray gun to meet the specific finish requirements for the application of the superior topcoat finishes supplied to the Marine, Yacht and Super Yacht New-build and Refurbishment markets. The DeVilbissCspray Gravity and Pressure guns unrivaled spray performance is achieved with the utilization of the very latest Critical Droplet atomisation Technology (CDT) DeVilbiss air caps.

All Cspray guns are precision built by DeVilbiss using the best materials and component parts for a guaranteed, reliable, long and durable working life in all industrial markets.

JGA Conventional

| Air Cap | Tip Size | Air Inlet Pressure | Air Flow @3.4 BAR / 50psi |

|---|---|---|---|

| 62HD | 2.8mm | 3.5 BAR / 50 psi | 502 l/m (18 scfm) |

| 64HD | 2.2mm | 3.5 BAR / 50 psi | 488 l/min (17.5 scfm) |

| 67HD | 1.8mm | 3.5 BAR / 50 psi | 539 l/min (19 scfm) |

| 69HD | 2.2mm | 3.5 BAR / 50 psi | 572 l/min (20.5 scfm |

Sizes available: 1.8mm and 2.1mm

The DeVilbiss JGA has long been regarded around the world as the spray operators first choice and it has earned an enviable reputation for quality,performance, durability and precision control.

Built to withstand continuous production line duty the DeVilibss JGA spray gun body is produced in drop forged aluminium and the replaceable air cap retaining baffle eliminates the need to replace the spray gun body should the threads become worn or damaged.

The extensive range of Air Caps, Fluid Tips and Needles are made to exacting tolerances providing excellent application and fluid compatibility.

Market and Applications

- All applications in the Ceramics and Glaze Industry

- Ceramic coatings and glazes

- Stove Enamels

- Most types of abrasive paints

- Difficult to spray and heavily bodied materials

The legendary DeVilbiss JGA spray gun sets industry standards for high production performance.

- The perfect gun for enamel, ceramic and glaze applications with forged aluminium gun body and removable body baffle for a longer working life.

- Wide range of stainless steel, hardened and tungsten carbide fluid tips and needles for heavy duty applications.

- Gun body with Stainless Steel fluid passageways for solvent and waterborne paints and superior corrosion resistance.

- Light smooth trigger action to reduce operator fatigue.

- “On gun” controls for air and fluid flow adjustment for optimum performance.

The legendary DeVilbiss JGA spray gun sets industry standards for high production performance.

The DeVilbiss JGA is a manual high performance conventional air atomising spray gun suitable for heavy duty industrial spray finishing and surface coating applications of abrasive, ceramic, enamels and difficult to spray materials.

FLG5

| Air Consumption | 368 l/min |

| Air Inlet Thread | 1/4″ Universal |

| Weight (gun & cup) | Gravity 642 gms, Suction 934 gms |

| Air Cap & Ring | Plated Brass |

| Fluid Tip | Stainless Steel |

| Needle | Stainless Steel |

| Cup capacity | Gravity 560 mls, Suction 1140 mls |

| Sizes available | 1.4mm and 1.8mm |

| Models | FLG-G5-14 / FLG-G5-18 |

| Application | Automotive, General Industry |

* NOT SUITABLE FOR WATERBORNE PRODUCTS

- Low cost spray guns for use with a wide range of general

- industrial paints and materials

- FLG-5 employ DeVilbiss TRANS-TECH® atomisation for paint

- saving efficiency, superb finishes plus compliance with EPA

- legislation

- Ultra lightweight, strong, cast aluminium gun body

- Ergonomically shaped gun handle for balance, grip and

- comfort

- Precision engineered brass air cap and stainless steel fluid

- tips and needles for long service life.

The DeVilbiss value for money spray gun range !

- FLG-5 is suitable for most routine spray jobs in the workshop and can also be used by DIY enthusiasts. This budget range of spray guns are available as spray gun kits in Suction and Gravity versions and there is also a Pressure gun option for the larger areas requiring fast coverage without the added down time of re-filling small cups.

- The low cost solution: Suction and Gravity guns are supplied in kits.

SRI PRO LITE

| Specification | Gravity |

|---|---|

| Air supply connection | 1/4" Universal |

| Maximum Static Air Inlet Pressure | P1 = 12 bar |

| Service Temperature | 0 to 40°C |

| Gun Weight | 395g (455g with cup) |

| Size | Fluid Tip Part Number | Needle part number |

|---|---|---|

| 0.6mm | SRIPRO-210-06M-K | SRIPRO-310-06M-K |

| 0.8mm | SRIPRO-200-08-K | SRIPRO-300-08-10-K |

| 1.0mm | SRIPRO-200-10-K | SRIPRO-300-08-10-K |

| 1.2mm | SRIPRO-200-12-K | SRIPRO-300-12-14-K |

| 1.4mm | SRIPRO-200-14-K | SRIPRO-300-12-14-K |

Typical Applications in General Industry

- Fine shading

- Retouching

- Stencilling

- Spot repair

- Reworking

Suitable for these materials

- Solvents and water based paints

- Stains and varnishes

- Inks and dyes

- Lacquers

The SRi Pro Lite spray gun is constructed of the very highest grade alloys and stainless steels to ensure smooth operation as well as high impact resistance. Every single component within the SRi Pro Lite spray gun is quality controlled and machined parts are checked to exacting tolerances.

DeVilbiss DeKup Disposible Paint Cups are available for SRi Pro Lite Gravity Spray Guns

The ultimate high precision touch-up and spot repair spray gun

- A small scale fine finish spray gun with many practical uses throughout general industry, ergonomically styled for comfort.

- Choice of HVLP or Trans-Tech® Compliant air caps provide superb atomisation of both solvent and water based materials

- Critically engineered Stainless Steel fluid tips & needles give ultimate feathering control

- Balanced air valve design for lighter trigger pull and improved air flow

- Lightweight, strong, cast aluminium spray gun body

- Reduced needle spring loading enhances trigger sensitivity

- SRi Pro Lite is supplied as standard with a quality screw-top gravity feed cup with 125mls capacity

- Optional inexpensive semi-disposable cups are available.

- A fine finish spray gun to provide ultra sensitive fan pattern control with the comfort of a full-size spray gun.

The Devilbiss SRI Pro Lite is the ultimate high precision spray gun providing superb feathering control combined with the pattern range and versatility needed for top quality finishing including spot repairs, shading and stenciling, whilst providing excellent comfort stability balance and delicacy of control. A new edition to the range is the SRi Pro Lite Micro which has been custom built for the high precision techniques used in the growing field of micro repairs.

PRI PRO LITE

Air Connection 1/4’’ Universal

Gun Weight (without cup) 446 g

Air cap Number and Type Recommended Inlet Pressure Air Flow @ 2 bar/29 psi

PR10 – Trans-Tech Compliant 2 bar (29 psi) 300 l/min (11 scfm)

PRi Pro Lite Gravity Fluid Tip/Needle (mm) size and code: 1.4, 1.6, 1.8, 2.0, 2.5

The all purpose Compliant primer spray gun

Large spray patterns and even material distribution

Suitable for all types of primers, surfacers, fillers and

polyesters

Air adjuster valve on the gun handle allows instant pressure

control

Balanced air valve design for lighter trigger pull and

improved air flow

Tough and durable drop forged aluminium gun body

Paint cup includes integral filter and drip-check lid.

The ultimate in primer spray gun technology

- The PRi Pro Lite is a mid sized compliant gravity feed spray gun specifically designed for the application of modern primers, surfaces and fillers. The all new PR10 primer air cap incorporates the latest DeVilbiss Trans-Tech atomisation technology for total compliance with EPA regulations. Primer guns must be compliant in their own right. The PR10 air cap is manufactured in plated brass for ultimate durability.

Specification

Air Connection 1/4’’ Universal

Gun Weight (without cup) 446 g

Air cap Number and Type Recommended Inlet Pressure Air Flow @ 2 bar/29 psi

PR10 – Trans-Tech Compliant 2 bar (29 psi) 300 l/min (11 scfm)

PRi Pro Lite Gravity Fluid Tip/Needle (mm) size and code: 1.4, 1.6, 1.8, 2.0, 2.5

Versatile

- Sprays automotive paints to waterbased inks

- Removable 1/3 oz. gravity cup, with optional 1/4 oz. and 1/2 oz. cups available, or spray with no cup

Comfortable

- Light weight and balanced

- Choice of trigger buttons

Durable

- Solvent proof fluid passages, PTFE® needle packing

- Copper, nickel and chrome plated body

High Quality

- Precision made in U.S.A.

Value

- Crown cap standard for fine lines and needle protection

- Collector storage tin included

Performance and Versatility for the Automotive Artist

- Lightweight, well balanced airbrushes with smooth double action trigger. Available in gravity or siphon feed.

Excellent Control

- Hairline detail to high paint-flow shading & gradual fades

- Smooth double action trigger

- Pre-set handle for precise control of paint flow